Walnut Dehulling & Separating Equipment TFHT-300

Component

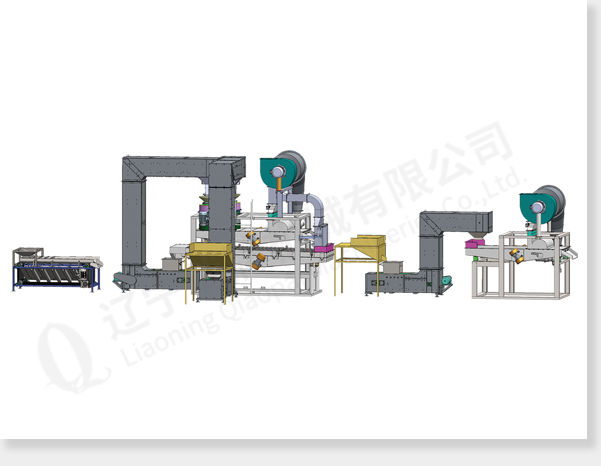

The equipment consists of 3 units and electric control cabinet.

Sizing unit consists of input hopper, Z-type elevator and sizing screens (the quantity of sizing screens varies with the raw materials).

Dehulling & separating unit consists of input hopper, Z-type elevator, dehuller ( for 1st time dehulling), separating sieve, C-type elevator (elevating unhulled walnuts to dehuller), dehuller (for 2nd time dehulling).

Shells-removing unit consists of input hopper, Z-type elevator, shell-kernel separator (1set). This unit can remove shells from kernels.

The equipment can grade, dehull and separate the walnut. It features high percentage of dehulling and whole kernels, easy operation and maintenance.

Technical Parameters

Please slide to the right

|

TFHT-300 |

Power |

Input Capacity |

% of Whole Kernels( Refers to 1/2 of whole kernel,raw walnuts is the thin skin walnuts) |

% of shells in kernels |

% of kernels in shells |

|

35.84kw(380v) |

300-400kg/h |

42%approx. |

10-15% |

0.5% max. |